years experience

Citra Vectory Tools - We are in manufacturing & supply of diamond dressers tools.

The entrepreneurs have rich experience of more than 35 years in diamond dressers & engaged in this business since 1990.

Citra Vectory Tools provides complete end to end solutions to its customers in the field of Diamond Dressers viz. we are specialist in customized solutions for our customers & have technical expertise & involvement in problem solving up to the shop floor level to ensure best of the results & output.

- Single point Diamond Dressers

- Multipoint Diamond Dresser

- Chisel Diamond Dresser

- Blade type Conical Dresser

- Diamond Wheels

- Roller Dressers

- Diamond Files

- Mono Crystal Diamond Needle Blades

- Diamond Paste

- CBN Wheels

Application industry of the diamond roller

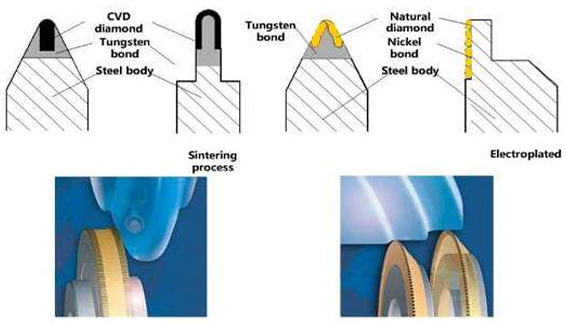

| Sr. No | Describe | MANUFACTURING PROCESS/BONDING | Diamond type used | EDGE PROTECTION | Remark |

|---|---|---|---|---|---|

| 1 | Dressing roller | Reverse sintered with tungsten bond | Handset Random CVD |

CVD Diamond |

The sharp is stable, use for CNC process |

| 2 | Dressing roller | Reverse sintered with tungsten bond | Handset Random |

Profile grinding for gear | |

| 3 | Dressing roller | Layer copper bond | Random | Self-sharpening for CBN | |

| 4 | Dressing roller | Electroplated with nickel bond | Random | Self-sharpening for CBN |

Application range of the diamond roller

- Drive part (gear, linear guideway, ball screw)

- Bearing

- Automotive (crankshaft, piston ring, needle valve nozzle)

- Tools (hobber, milling, drilling)

CNC-roller

Through the CNC program move the dressing disc, the grinding wheel can be shaped.

Advantage:

- CNC roller can be used on the grinding area, especially in sample processing applications.

- The price is cheaper than profile roller, and it can be used on different shapes of rollers.

- It uses natural diamond or CVD for the corundum wheel; reshape roller is used for CBN wheel.

- The CNC roller uses the sintering process.

Product line

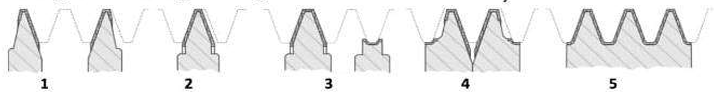

For gear worm grinding

- 1. Set of diamond dressing discs

- 2. Dressing roller double cone

- 3. Double cone with OD dresser

- 4. Dressing roller assembly

- 5. Multi-rip roller

Advantage:

- All the worm rollers use the sintering process; the life is long.

- The roller can be customized.

- CVD is used at the top of the roller for reinforcement.

- The accuracy is less than 2μm.

Used for machines: KAPP, Reishauer, Liebherr, Gleason, SAMPUTENSILI...

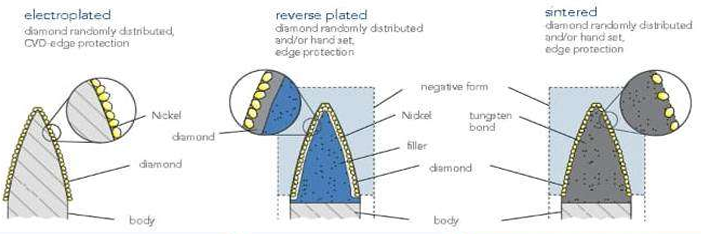

Overview of the manufacturing process

Scattered

- Can be influenced by griding

- Aggresive dressing behaviou

- Can be stripped and replated several times

Scattered (set)

- Large diamond surface

- High accuracy

Set (scattered)

- Controller diamond surface

- Can be influenced by grinding

- Very good diamond bond

- Good head disipation from the diamond

Diamond Type : Hand set, Random, CVD diamond

Test Equipment

This is the machine taylor hobson, the type is PGI-830, The test precision is 0.8 (µm)